Our products

We have the solution

Developing the electrolyser technologies that make green hydrogen universal.

The lowest cost of green hydrogen

Polymer Electrolyte Membrane (PEM) electrolysis is the lowest cost, most efficient technology on the market for the 1-10MW range, which is our initial target market.

Our innovative, proprietary solutions blend performance and durability in systems to deliver market-leading operational and capital efficiencies.

Our technology is driving down the cost of green hydrogen

The benefits of Polymer Electrolyte Membrane electrolysis:

-

Utilisation time

Wide window of operation leads to higher utilisation

-

Electricity cost

Decreasing costs of renewable energy

-

System cost

Low cost design built for scale manufacture

-

Asset lifetime

High durability ensures minimal asset maintenance required

-

System throughput

High production rates drive lower CAPEX

-

System performance

High efficiency means low OPEX

The benefits of Oort Energy’s Electrolyser:

-

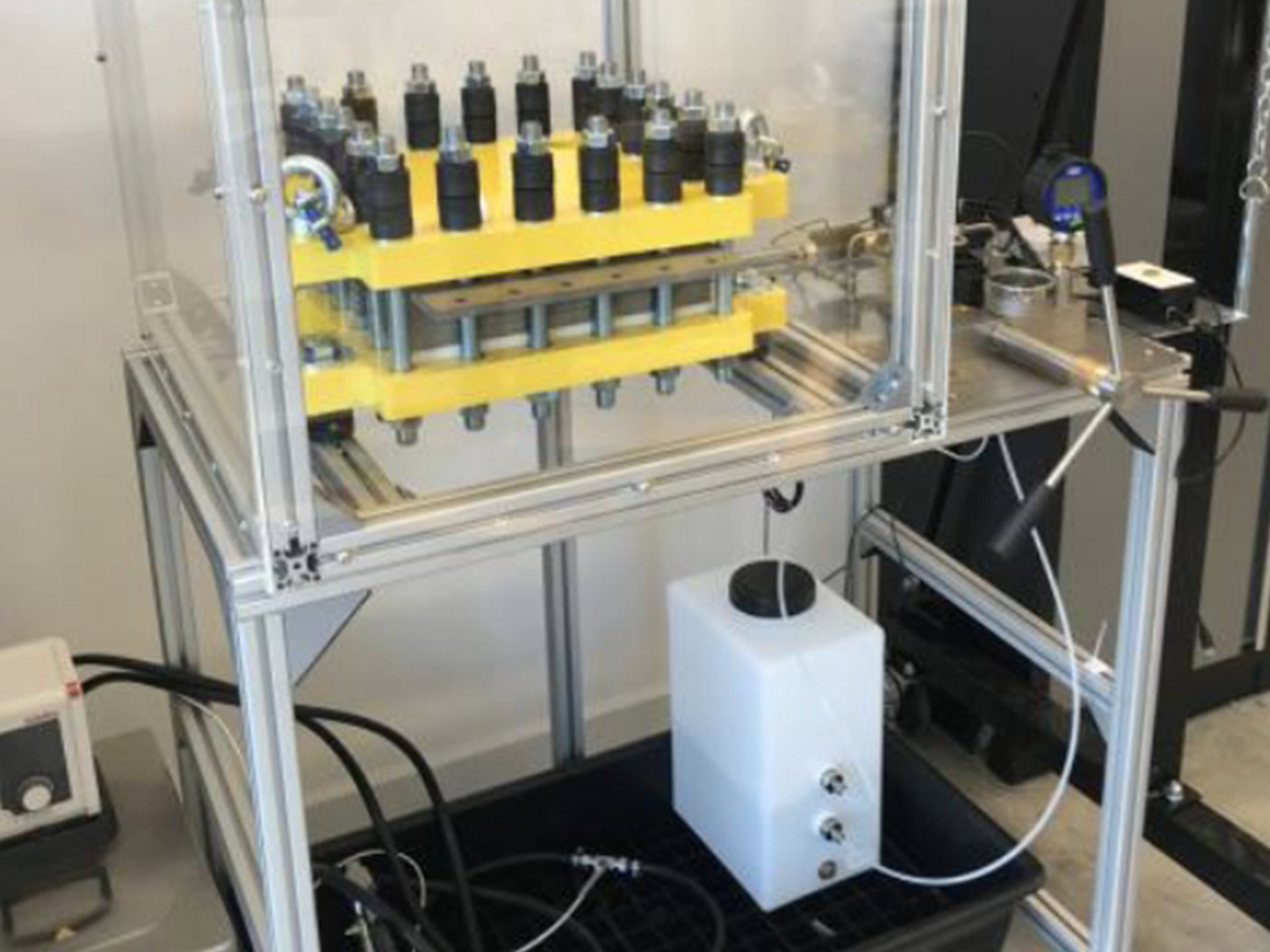

Novel low cost stack design

-

Novel MEA that allows unparalleled performance

-

A bipolar plate coating that increases lifetime

Key milestones

Durability

More than 1 year of durability testing

Mechanical failure mechanisms designed out and tested

Pressure testing to 100 Bar (differential)

Design

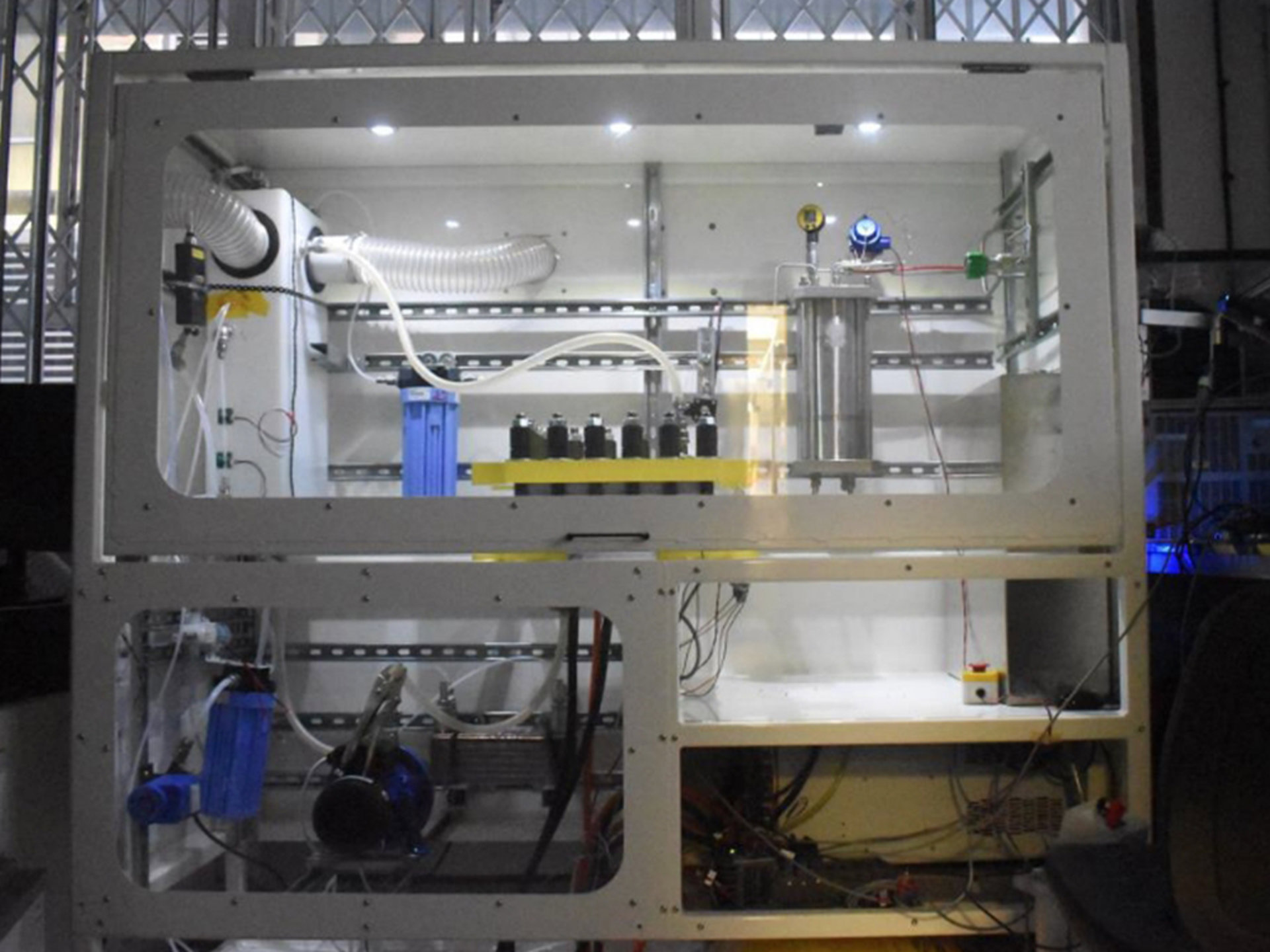

250 kW Industrial Demonstrator

Final stack design built and tested

Automation of control system

Best in class efficiency demonstrated

Design for 1MW containerised systems in development

Commercial

£6M seed funding raised

£2.5M+ Revenue from customer orders

Two patents filed (three more to file)